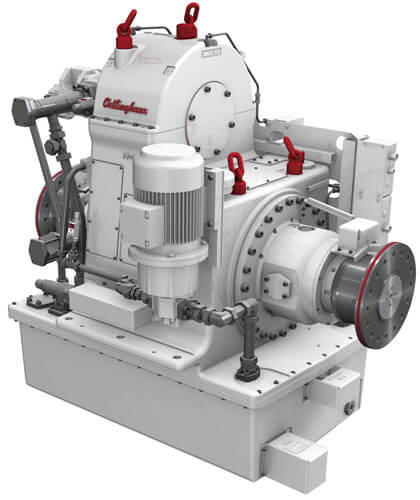

INDEPENDENT

TROLLING SOLUTION

Steplessly vary the propeller

rotation at constant

engine speed.

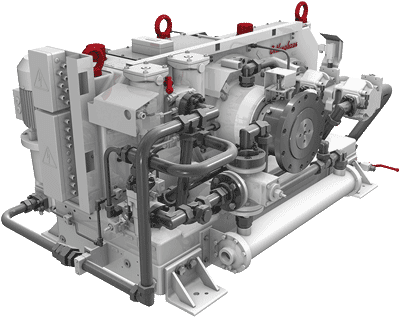

Variation of propeller rotation

at engine idling speed

Variation of propeller rotation at nominal

speed, full firefighting pump output and

simultaneous low propeller rotation for

holding position via drive system

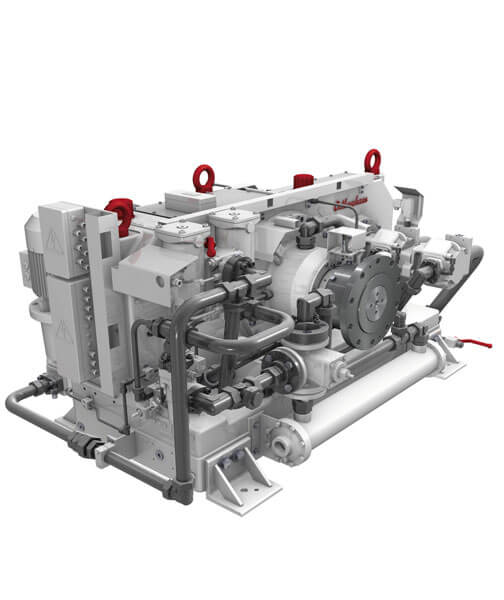

| Version | MD | HD | |

|---|---|---|---|

| Size | 66 | 72 | 75 |

| Power * | 2.900 kw | 4.150 kw | 2.750 kw |

| Speed * | 1.800 min-1 | 1.600 min-1 | 750 min-1 |

| P/n | 1.65 | 2.62 | 3.7 |

| Torque | 15.750 Nm | 25.000 Nm | 35.650 Nm |

| Heat dissipation | 45 kW | 90 kW | 450 kW |

All features in one clutch-system.

Full propeller control.

Fast reaction times, global presence and extensive know how of our Service Team make the difference.